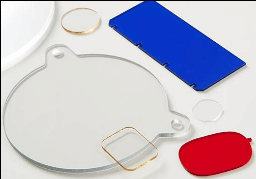

TSP can provide them for: optoelectronic display fronts, instrument cluster panels, contrast enhancement filters, ruggedized flat panel displays, bar-code scanner windows, moving message board signs, and much more. Whatever your protective viewing application, TSP has a quality, cost-effective, high-performance DURAVUE® solution for you.

Batavia, Ohio – April 30, 2025 TSP, Inc., an industry leader in protective plastic for durable viewing applications, is pleased to announce today that we have earned renewal of our ISO 9001 certification. The comprehensive system audit covers every aspect of operations. “We appreciate the recognition of not only achieving ISO 9001 registration renewal, but … Continued

Adding a hardcoat to polycarbonate extends the useful life of a product or part by 5-10 times vs. uncoated due to several key benefits: Scratch Resistance Chemical Protection Optical Clarity Durability Consider the value of adding one of TSP’s suite of DURAVUE® hardcoats to your polycarbonate part. Our DURAVUE® hardcoat extends in-use service life and … Continued

Question: What makes TSP’s DURAVUE® 2000 Anti-Glare Hardcoat superior to other leading anti-glare treatments for polycarbonate or acrylic display applications? Answer: DURAVUE® 2000 Anti-Glare Hardcoat is superior to alternative anti-glare offerings for several reasons: Outstanding Abrasion Resistance: DURAVUE® 2000 AG offers superior abrasion resistance versus simple matted surfaces, which means it can withstand more wear … Continued

Manufacturing is indeed returning to the United States, due to several factors: Less Supply Chain Disruptions: The COVID-19 pandemic exposed vulnerabilities of distant global supply chains. Supply chains are more resilient by manufacturing in closer proximity to customers and markets. Shorter Lead Times: Keeping operations in the U.S. allows companies to source materials more quickly … Continued

As a leading supplier of durable plastics for protective viewing applications to many of the world’s most demanding companies, we recognize our responsibility to be properly aligned with our clients in all aspects of our operations. This includes ESG. We take how we operate relative to these matters seriously and encourage you to explore our … Continued

Working with a supplier should not be a worrisome chore. It is often difficult nowadays to simply get what you want, when and where you need it. That is what makes working with TSP so refreshing. Our customers tell us they appreciate our responsiveness and flexibility in helping them meet their demanding delivery schedules. To … Continued

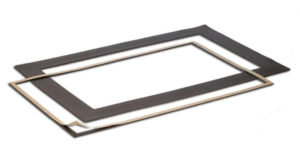

You have a plastic window and are unsure of how to bond it to your display or data acquisition device – what is the best method? Liquid glue? Sonic welding? Adhesive tape? Liquid glue is difficult to apply and messy. Sonic welding takes specialty equipment, is limited to certain materials and requires 3D geometries. Adhesive … Continued

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Tell us about your project and we’ll provide you with a budgetary quotation.

Tell us about your project and we’ll provide you with a budgetary quotation.