DURAVUE® Coatings allow for the use of Plastics for Viewing & Data Acquisition Applications

Q: Why would I use a plastic window, filter or lens instead of an alternative like glass?

A: Plastics with a DURAVUE® coating offers improved Durability and Design Flexibility

Durability

Glass is not suitable for most high traffic or portable product applications due to its susceptibility to breakage upon impact or when dropped in use. Durable, impact-resistant engineered plastics like polycarbonate are an excellent replacement, but are highly susceptible to scratching and abrasion. Adding a DURAVUE® scratch resistant coating to polycarbonate provides you with a durable window, filter or lens with a longer usage life due to the reduced possibility of breakage.

Design Flexibility

Plastics are significantly lower in unit weight than glass. When added to the breakage issue, a much thicker glass window is required to match the durability performance of a much thinner plastic window, resulting in an even greater comparative advantage. This difference in gauge thickness of the window can be an important design consideration where there are space and/or weight limitations.

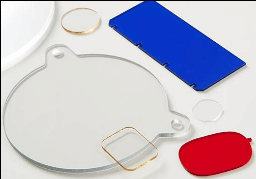

Plastics are also easier to manufacture (fabricate, mold, form) into more complex product shapes/geometries than glass. The boom in plastic parts production in the automotive and safety/security markets over the past few decades was a direct result of the development of siloxane-based hardcoats like DURAVUE® that allowed the replacement of glass lenses with the easier to mass-manufacture plastic coated lenses.

With a greater array of filtering colors available for plastics than typical in glass, designers can make greater use of color to manage light for their contrast enhancement filters and other electronic display windows, or to filter light in their data acquisition lenses. Add in the opportunity to provide superior anti-glare or anti-reflection properties with a DURAVUE® coating, and you have a significant design advantage over glass.

All DURAVUE® coatings are durable! DURAVUE = Durable Viewing

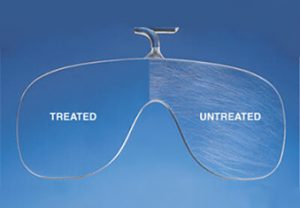

One of the unique features of our DURAVUE® family of coatings for plastics – whether it is for anti-scratch, anti-glare or anti-reflection – is that each provides the same superior scratch resistance, protection against harsh chemicals and weathering, and ease of cleaning/maintenance. For example, most anti-glare coatings/methods do not include scratch resistance, especially where the surface is mechanically etched at the material manufacturing phase to achieve the glare reduction via a matted surface. This leaves the plastic surface susceptible to abrasion, weathering and chemical attack, making it not durable for extended use. The same goes for most anti-reflection coatings, which are also especially hard to clean without “smudging” the surface. Whichever DURAVUE® coating you select for your particular application, you are assured it will provide durability to extend the life of your product.

Anti-Glare Plastic for Displays

Anti-Glare Plastic for Displays  Need a Durable Clear Plastic?

Need a Durable Clear Plastic?  Anti-Glare vs. Anti-Reflective

Anti-Glare vs. Anti-Reflective  Which is the best material to use for your display or data acquisition window?

Which is the best material to use for your display or data acquisition window?  See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Tell us about your project and we’ll provide you with a budgetary quotation.

Tell us about your project and we’ll provide you with a budgetary quotation.